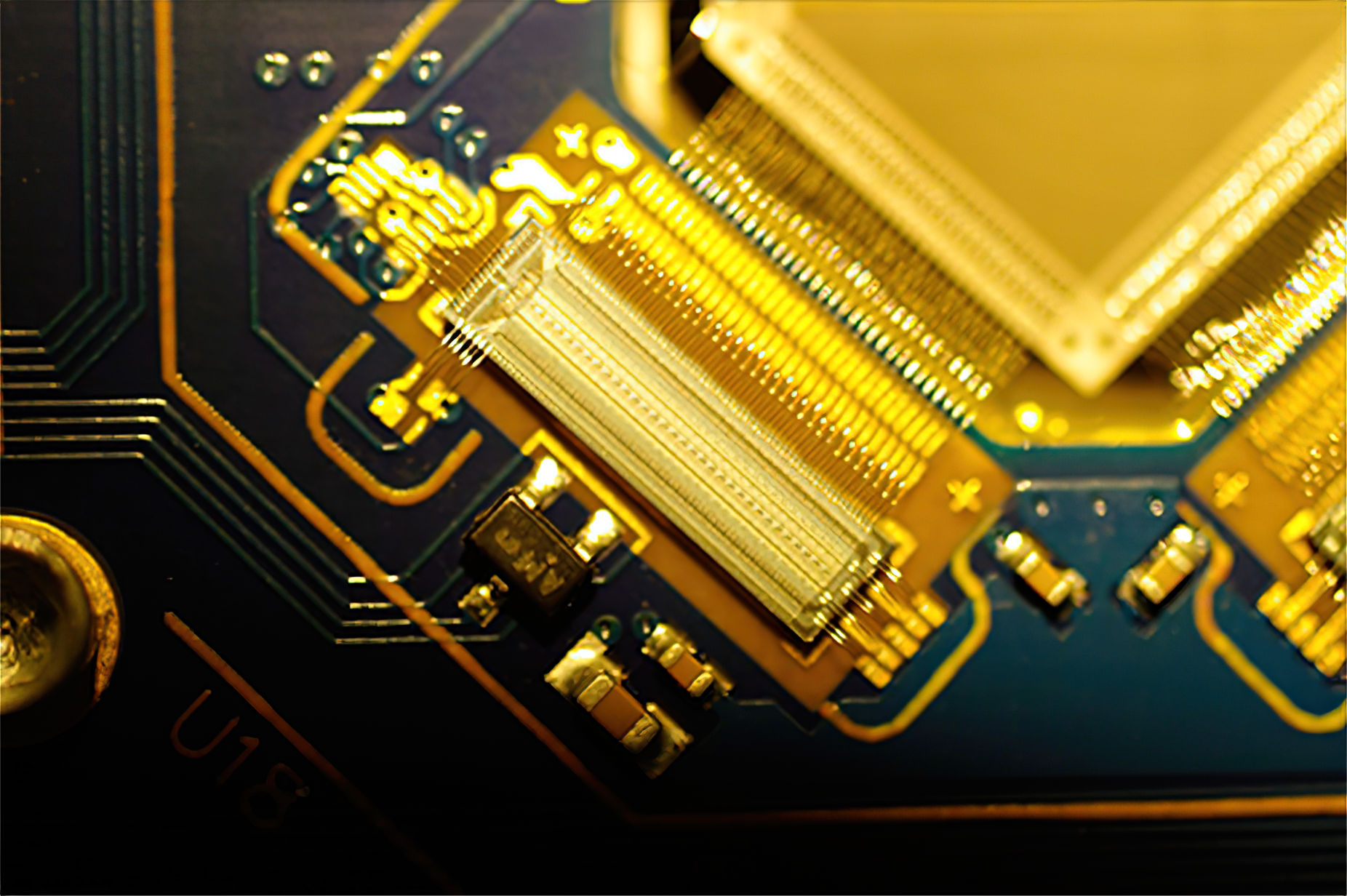

Packaging & Assembly

Teledyne MEMS provides a wide range of technologies to assemble and package customer and application-specific products. From bioanalysis to commercial printing to optical sub-assemblies, we have the expertise, experience and toolsets to successfully manufacture most MEMS-based assemblies.

Our MEMS assembly capabilities include:

- Discrete die-level packaging

- Spot welder

- High-vacuum furnace for getter activation and hermetic package sealing

- Semi-automated die sorter

- Die/flip chip bonder

- Low temperature co-fired ceramics

- Solder die attach

Die-level packaging

Teledyne MEMS performs both traditional and novel die-level packaging for MEMS devices. Our expertise includes wire bonding to external packages, hermetic sealing of packages using various bonding methods, and die-level electrical testing of devices in a low noise environment.

Wafer-level packaging

Our unique wafer-level packaging (WLP) process platform for MEMS devices provides an all-in-one customer solution, integrating wafer level fabrication, hermetic packaging and through-silicon-via (TSV) architecture.

The design kit reduces initial development cost, ultimate manufacturing component cost, footprint, thickness and weight, while providing improved electrical performance, reliability, and extensibility into 3D IC designs where electrical connections to be formed inside the die cavity.

WLP for inertial sensors

Our platform is a proven, cost-effective solution for applications requiring high accuracy, low-noise mechanical sensing by devices operating across wide frequency ranges and requiring high vacuum encapsulation.

Features include:

- Insulated Through Silicon Vias (TSV) – polysilicon filled

- Thick silicon device layer (60 microns standard) for high comb finger capacitance

- Lead-free solder ball grid array

- Wafer level bonding processes optimized for getter film activation and hermetic sealing

Wire Bonding

- High speed automated wedge wire aluminum/gold deep access

- Automated ball wire (Au) bonding

- Wire bonding from dice to submount, dice to package, submount to flex cables

- Wire bonding equipped with PRS

- Wire size capability from 17 – 75 µm

- Substrate size up to 200 mm X 150 mm

- Position repeatability typically ± 3 µm

- Multi-chip, multi-module wire bonding capability

- Wire bonding capability from dice to package and dice to sub-mount

- Packaging capabilities include flex cables, mounting substrates, packages compatible with optical technologies

Teledyne MEMS Capabilities

We blend MEMS applications experts together with process performance champions to design process flows for robust, cost-effective fabrication to match customer requirements. Our project teams strive for deep insights to their customers’ needs and close communications throughout the relationship.

Do you have any questions?

Select Teledyne as your partner to move your MEMS device from concept to mass production.

Contact usStay connected

The MEMS industry is evolving quickly with new innovations, applications, and events. Subscribe to our newsletter and we’ll help you keep up to date with the latest developments

Subscribe